Center for Improving Oilfield Development Methods

at the Academy of Sciences of the Republic of Tatarstan

at the Academy of Sciences of the Republic of Tatarstan

Simulator for the operation of wells equipped with ESP Systems

The mockups that simulate operation of real ground equipment are virtual, poster and full-scale analogues of ground equipment, equipped with sensors, actuators and regulators to implement the functions of the simulator.

More...

Relevance of the simulator for specialists operating wells equipped with ESP systems

More than 80% of Russian oil is produced by ESP SYSTEMS

A comprehensive interactive simulator is designed to train and upgrade qualifications of specialists in the operation of wells equipped with electrical submersible centrifugal pump (ESP) on mockups that simulate real ground oilfield equipment (GOE) with the ability to model and track the processes occurring in the virtual system "layer - oilwell - ESP - GOE"

Fire hazardous - oil. 17% of accidents are due to "human factors"

46%

violations of equipment tightness

22%

external man-made impacts

17%

staff errors

simulator task: ensuring the safe operation of wells, reducing negative influence of the "human factors"

15%

external impacts of a natural cause, uncontrolled release of oil or gas from a well

Versions of the simulator:

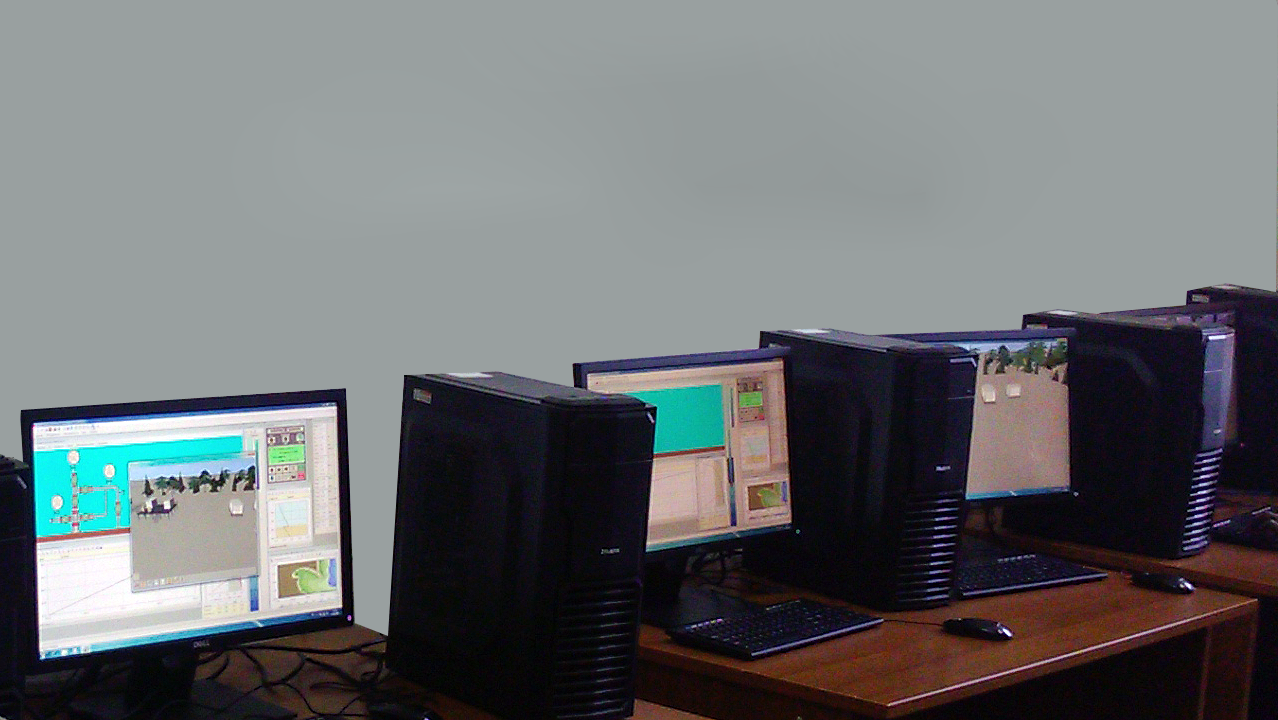

Computer simulator

Automated learning system: field scene, well, reservoir, ground and underground equipment of ESP Systems are implemented as virtual 2D/3D models. Computer simulator based on software "ARMARIS" is a software platform for all versions of the simulator.

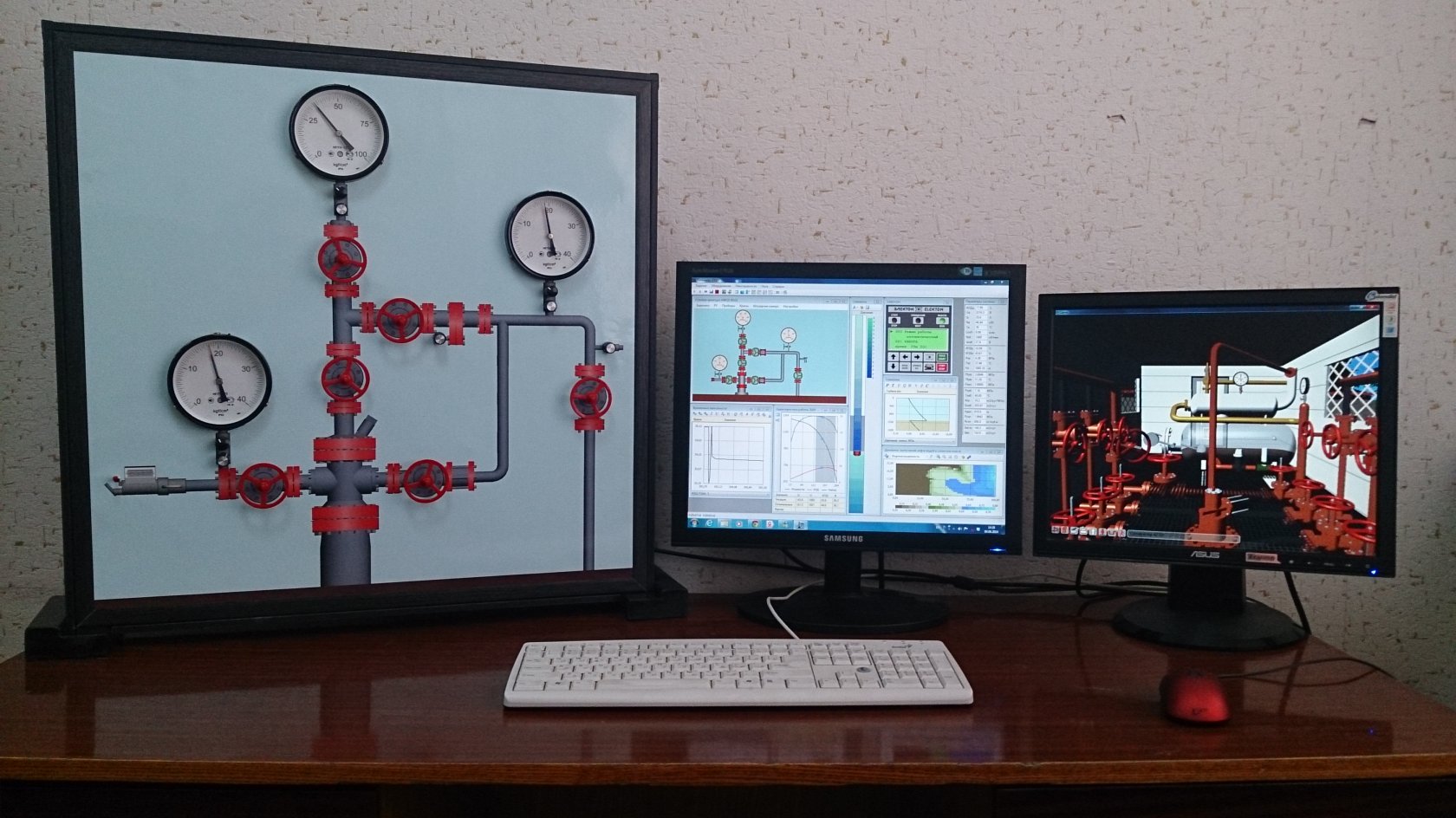

Portable simulator

Specialized simulator: ground field equipment - compact layots and devices. Submersible equipment - a virtual 3D model. Mockups are connected to computer and are equipped with sensors and electric drives that simulate processes and actions, creating the illusion of the real work of field equipment.

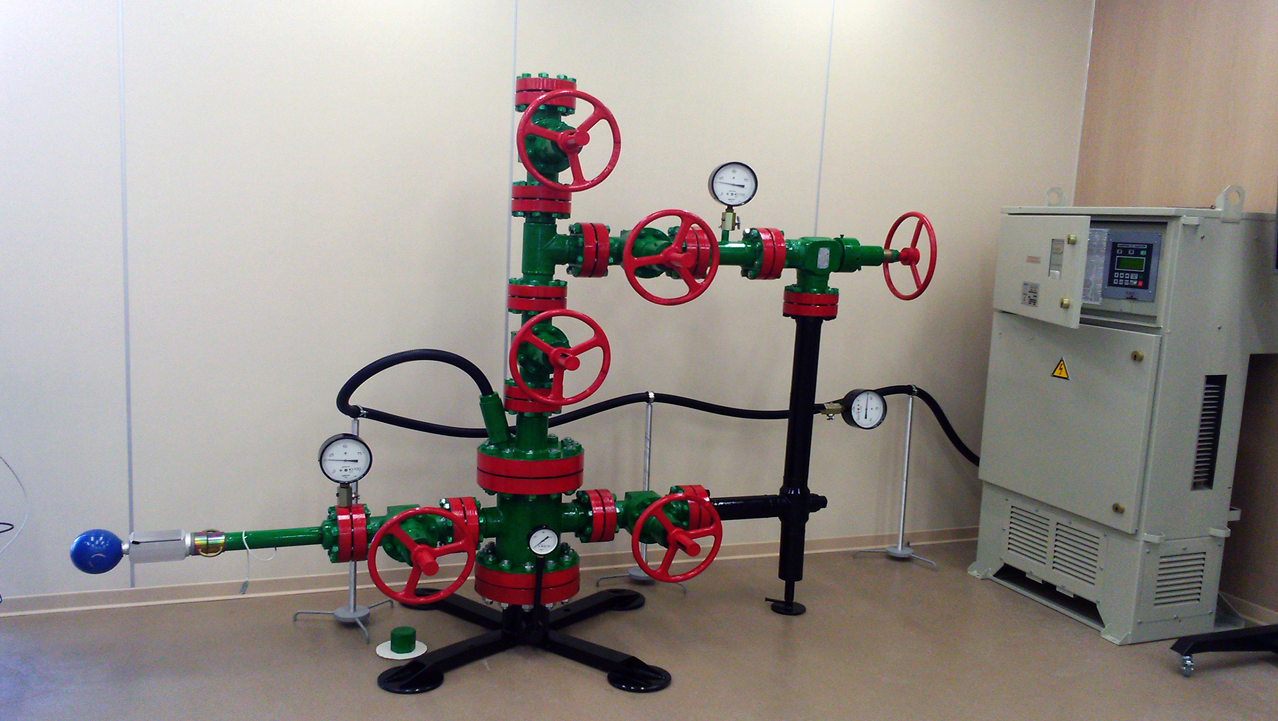

Full-scale simulator

Comprehensive full-scale simulator: ground-based field equipment - full-size mockups: "Electon – 05–250" control station; Wellhead fittings (AFKE1 65 × 21 and ANK 65 × 21); echo sounder "SUDOS mini 2". Submersible equipment - virtual 3D model.

The advantages of our simulator

This is the best way to improve your professional knowledge, skills and become valuable specialist in the operation of wells equipped with ESP systems

Effective training

of operators, students to perform routine in the operation of real field equipment and solving practical problems of oil production using wells equipped with ESP systems

Mathematical model

simulates the movement of a multiphase oil – water – gas mixture in an interconnected system "Reservoir – borehole – ESP systems"

Full-scale simulator

with the closest possible simulators of devices and equipment to the real working conditions of oil workers

IT products in the simulator

They function both in conjunction with the simulator and autonomously. Can be used on smartphones and tablets.

Online reference guide ESP-Expert

The simulator's software includes the ESP-Expert reference guide, which is intended for viewing, entering and processing the characteristics of submersible bladed pump units with the electric drive. Online reference guide ESP-Expert can operate autonomously.

3D scene of an oil field cluster

The simulator software includes a 3D model of an oil field cluster, which contains the underground part of the well, wellhead fittings, testing gas separators. When opening a 3D scene in simulation mode, the exchange of data with 2D models of ground field equipment begins when the well is placed on the mode and the start-up of the well after the repair. All interactive elements of the 3D scene and 2D models work synchronously. 3D scene can work offline.

Introductory course

This document provides information on the main elements of oil fields, and also explains principles of some equipment for operation in wells equipped with ESP (electrical submersible centrifugal pump).

Training on the combined simulator

We are ready to show and demonstrate all the functionality of our innovative developments for teachers, students of oil technologies and universities, specialists of oil enterprises, researchers who study the processes of oil recovery

Questions and answers

Do you have any questions? Answers are below.

Our customers

Professional contacts with the developer of simulators allow creating not only new forms of academic disciplines, but also professional standards.

Three Level Learning System

1st level: computer simulator

Automated learning system. Mathematical models of the operation of the reservoir – oilwell – ESP system have been implemented. The computer simulator implements the principle of conceptual development of the main and auxiliary equipment, allows the operator to work out the basic modes of operation of the well, to detail the knowledge of the operational schemes and functional capabilities of devices and equipment.

2nd level: portable simulator

Desktop mockups of devices and equipment are connected to the computer simulator. A specialized simulator, using mockups (portable stands), simulates elements of onshore oilfield equipment and processes in the reservoir – oilwell – ESP system, which makes it possible to work out and acquire skills, knowledge, and ability to control individual technological processes.

Level 3: full-scale simulator

Full-scale ground equipment models are connected to the computer simulator. The simulator using real ground full-scale equipment of the oil well cluster imitates the work on the operation of wells equipped with ESP, which allows to consolidate the knowledge, skills and abilities obtained at previous levels.

Awards

Bronze Diploma

Competition of energy efficient equipment and technologies in the framework of the seventh International specialized exhibition "Energy. Resource Saving".

Bronze medal

V Moscow International Salon of Innovations and Investments.

60

licenses of software "ARMARIS" acquired by experts, educational institutions and enterprises of the oil industry

8

We introduced 7 full-scale simulators into the training processes of universities and oil-oriented training centers

4

portable simulator installed and used in the educational process of the Russian University of Peoples' Friendship (RUDN), Moscow and Budgetary Institution of Professional Education of the Khanty-Mansiysk Autonomous Okrug - Ugra

Supply and installation of a full-scale simulator

1

Technological staff training before delivery

Compulsory training/ internship of specialists from the developer – manufacturer LLC СSMRneft.

At least 2 specialists.

Training period - 4 days.

At least 2 specialists.

Training period - 4 days.

2

Delivery and installation

The weight of a full-scale simulator is ~ 500 kg. We install on a concrete floor - on a special stand. If the classroom is above the first floor, then a concrete floor is required between the floors. The simulator occupies ~ 20 square meters + study places for students (tables with computers, chairs). The area of the class can be from 50 sq.m. The required voltage is 220 V to 1 kW. All activities are done by us.

3

Technical support

2 years warranty service.

Contacts

Yuri Andreevich Volkov

General Director of СSMRneft LLC, Kazan

Phone: +7 987 290 26 47

E-mail: yua@csmr.ru

E-mail: yua@csmr.ru